While researching I found that a reputable digital fabricator/ architect Mark Fornes "Thevermany" is doing a much more complex but similar project http://www.theverymany.net/labels/weaving.html.

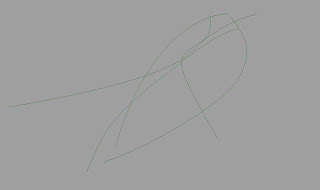

Here is a little about my process I took five curves that I wanted to be the dowels suppporting the vertical planes

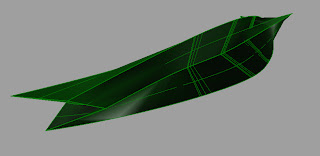

Once I had these curves I lofted them as straight sections rather than the normal curvilinear style and selected a closed loft resulting in this shape.

After I had this form I needed to make a place for the dowels to run through, so I used the pipe command on the same curves that I lofted and made them a 1/2" diameter and booleaned the loft and the pipe together.

After I had this form I needed to make a place for the dowels to run through, so I used the pipe command on the same curves that I lofted and made them a 1/2" diameter and booleaned the loft and the pipe together.

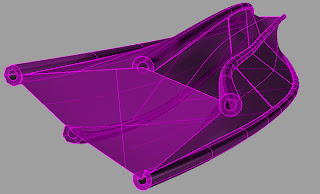

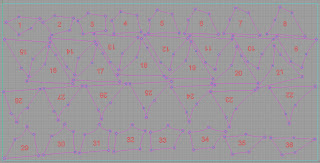

Then still using the same curves I once again used the pipe tool, but this time I made the pipe a 1/4" diameter and used the boolean-difference tool to make the 1/4" pipe hollow. Then I contoured the form ever 1 1/2" and layed it out for laser cutting.

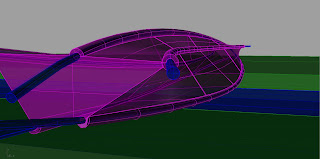

This is also the project that I will be rendering in a architectural setting and here's the camera angle I'm rendering.

This is also the project that I will be rendering in a architectural setting and here's the camera angle I'm rendering. Building this was quite the treat. I took 5 1/4" dowels and 360 1/4" e-clips. The e-clips go on both sides of the vertical planes on all 5 dowels. I made a jig with spacers to get the correct 1 1/2" spacing between the contours.

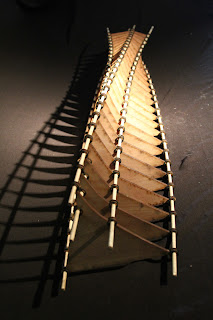

Building this was quite the treat. I took 5 1/4" dowels and 360 1/4" e-clips. The e-clips go on both sides of the vertical planes on all 5 dowels. I made a jig with spacers to get the correct 1 1/2" spacing between the contours.

So here is the final product in some sexy lighting

So here is the final product in some sexy lighting

Nice posting thomas. i can't wait to see. i still feel that there may be some advantages to using flexible tubing for you connections.

ReplyDelete