Saturday, April 26, 2014

Blake Gunderson - Laser Engraving

Maya rendering of 3D Sculpture

Engraving

Brush design I made in Illustrator

Engraving

Made in Rhino

Exported lines into Illustrator

Engraving

Leaves, converted to lines in illustrator

Engraving

Blake Gunderson - Slotted Structures

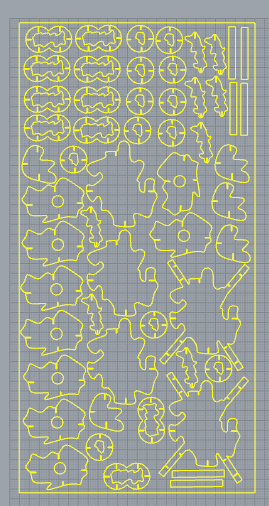

Rhino Layout

Made slotted shapes on a 24x48 layout to be laser cut.

Laser cut shapes

Assembled and painted with metallic paint

Assembled and painted green

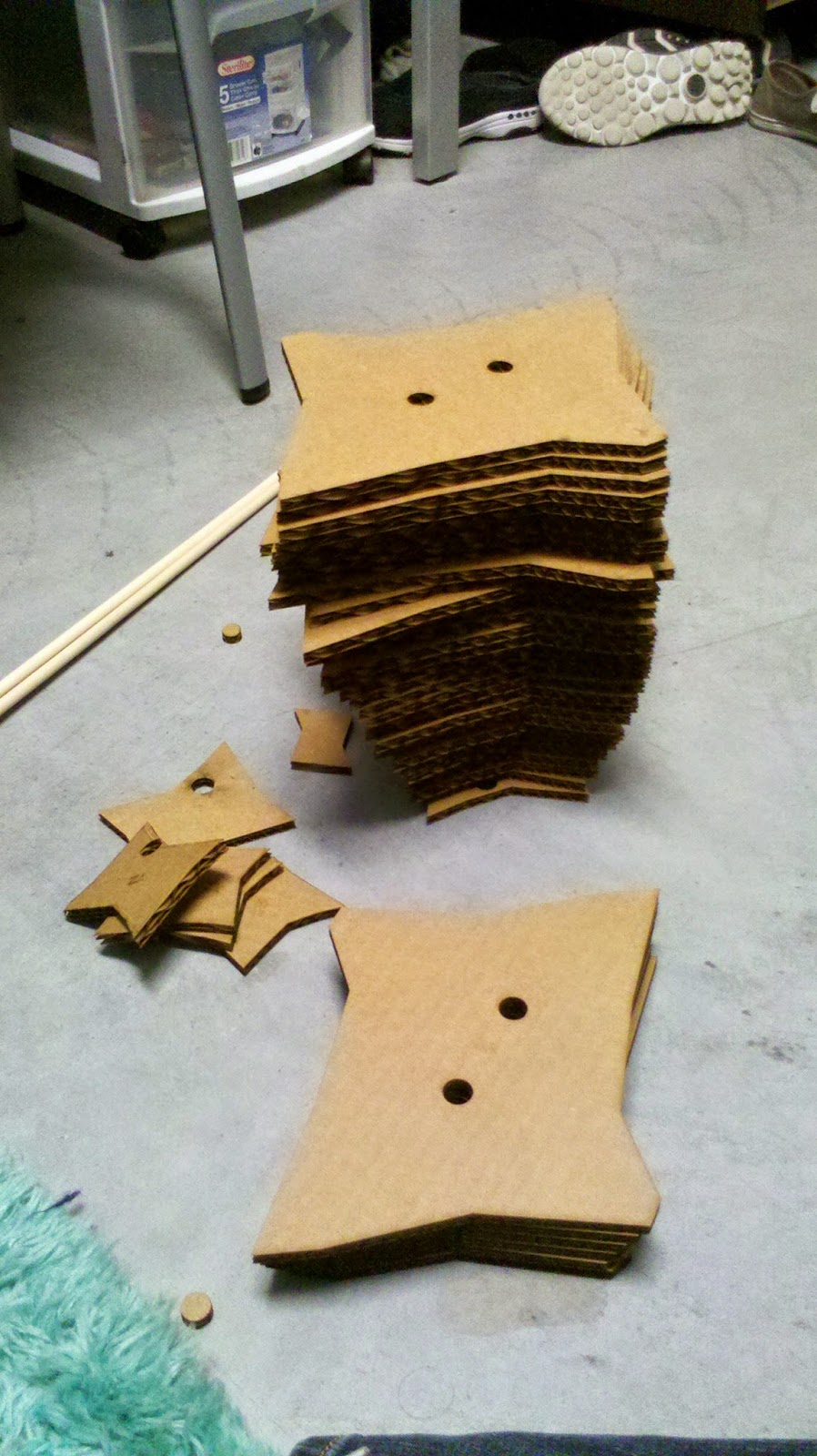

Blake Gunderson - Serial Slicing

Serial Slicing

Model created in rhino

( Thickness of the cardboard )

Layed out single surfaces for the laser cutter with numbers to keep them in order.

Pieces after laser cutting.

Used .25" dowels through the holes to keep each piece aligned

Glued together with loctite professional

Blake Gunderson - 3D Scanner

Clay Model for 3D Scanner

Painted white and added registration dots for aligning after scan is complete.

Scanning Process

NextEngine 3D Scanner: Scanning into ScanStudio Software

Fused & Cleaned Up In Rapidworks

Exported mesh created as an obj.

Imported into Rhino and reduced poly count for a more geometric look

Monday, April 21, 2014

Rebecca Blessing - 1st Serial Slicing

Made a simple form in Maya using deformers on a nurbs surface and imported it into Rhino. Placed two cylinders through object as guides.

Sliced the model up into sections and isolated the curves

Laid out and numbered the slices on sheets to be cut out of the cardboard.

I got the pieces cut out with a laiser and arranged them in order by number. This is the point where i realized my wooden dowels were two small.

I started gluing anyway lining the holes up by eye

After finishing what i had i realized i was missing half of the required slices... so back to Gulfstream i went

Due to an cardboard mix up, the model came out stretched and much larger than planned.

A happy accident in my opinion as the end result is very pleasing.

A happy accident in my opinion as the end result is very pleasing.

Slots

3-D scanning

This is an object which was made for 3-D scanning. The form was made from Sculpey which was baked, painted and marked with alignment dots.

The form was then scanned through Scan Studio where it was aligned. Afterwards it was loaded into Rapid works and the form was fused, polishes and saved in OBJ and IGS formats

Files in Rhino

When files were uploaded into Rhino the form could be manipulated and made into various tangible objects like 2-D engravings.

Subscribe to:

Posts (Atom)

.jpg)

.jpg)

.jpg)