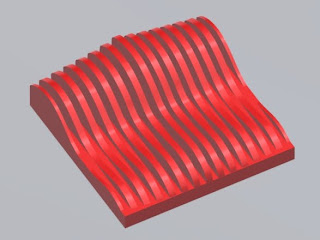

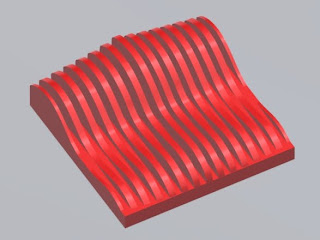

My inspiration for the CNC Milling project stemmed from landscapes. I wanted to create an abstract landscape that would carry the abstraction into the vacuuming process. My form was created in Rhino, I created each individual shape and edited surfaces from there to establish a wave typology within the surface.

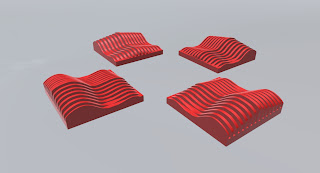

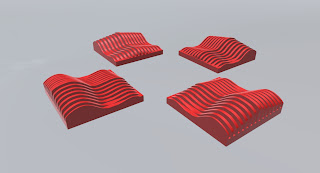

Once the milling process is through, I plan to create a series of vacuum forms and shape them similarly to the picture below, with the potential of using more than four. The final product will be a wall piece.

After receiving my CNC model and rubber model back, it was time for some smooth cast DOPENESS!

First five minutes:

harding up at 6 minutes

harding up at 6 minutes

Ten minutes

On to the next one after 15 minutes

Once the milling process is through, I plan to create a series of vacuum forms and shape them similarly to the picture below, with the potential of using more than four. The final product will be a wall piece.

Once the milling process is through, I plan to create a series of vacuum forms and shape them similarly to the picture below, with the potential of using more than four. The final product will be a wall piece.

After receiving my CNC model and rubber model back, it was time for some smooth cast DOPENESS!

After receiving my CNC model and rubber model back, it was time for some smooth cast DOPENESS! harding up at 6 minutes

harding up at 6 minutes

Carleigh, this posting needs and update, where are the pictures of the work in progress. a hypershot rendering would be nice.

ReplyDeleteSmooth cast dopeness. i guess i got my update.

ReplyDeleteIt is advised to make a note of some questions to ask before calling the companies, this makes it easier to compare each company based on the criteria you have chosen.

ReplyDelete